Design of Machine Elements Cam and Spring Assignment

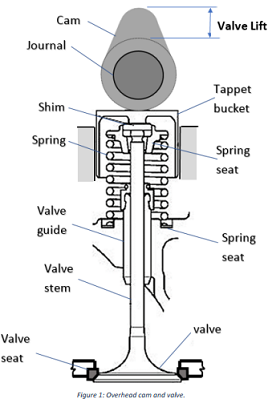

Cams have been used to provide well-timed lift to engine valves since the very early motor cars of the 1900s. Springs (coil type) have been used throughout the same time period to hold cam followers against the cam surface and to close these engine valves.

The T model Ford employed three-arc cams in its engine. This type of cam as well as other circular arc type cams were widely used in automobile engines until the 1950s. They were relatively easy to draw on the drawing machines of that era and to manufacture using the machine tools available during those times.

For this project, you are asked to

1. Construct a three or four arc cam profile in accordance with the data that you are given.

2. Calculate the rise, velocity and critical accelerations by the analytical method discussed in the lecture. You may also wish to construct the rise, velocity and acceleration diagrams for this cam. This will help you visualise the movements of the valve.

3. Calculate the critical inertia forces developed in the components of this system. These occur at beginning of rise, tip of the nose and end of descent of the follower.

4. Tentatively size the valve spring based on the peak inertial loads obtained from the valve train motion. Use an estimated mass of the moving elements in the valve train. You are given the combined mass of all moving parts except the spring. Initially assume that the mass of the spring is equal to this given combined mass and that this springs dynamic effect is 50% of its mass. Make sure that the spring provides sufficient force to seat the flat follower on the cam at times, especially at the tip of the nose. For this purpose, allow a 20% factor of safety - i.e the spring compressive force should be 20% greater than the opposing inertia force.

5. Re-calculate spring details as in step 4. using the actual spring mass as calculated from the details determined in step 4.

6. Repeat steps 4. and 5. until the parameters have stabilized. This may only take two or three iterations.

7. Size the width of cam and follower pair after checking Hertzian1 stresses at the cam and follower surfaces.

8. Draw the cam profile and produce a manufacturing drawing showing all crucial features of the cam. A cam shaft, containing your cam would be machined out of a forged bar, possibly having journals each side of the cam. Assume that there is a journal of diameter and length equal to 80% of the cam's base circle diameter. Fully specify both spring and cam material including appropriate bulk and surface properties, heat treatments and surface finish.

9. Summarize your design process in a brief engineering design report. This design report should contain the following.

- A statement of your specific design problem.

- A description of your design procedure.

- Samples of all design calculations. These could be submitted in an appendix.

- The drawings and specifications that you have finalised.

- A discussion on the limitations of your design.

- A statement that your design should not be applied outside these limitations.

Finally, you should do some relevant research yourself, then describe the limitations and problems of the circular arc cams.2 You should also discuss, in general terms, the fact that later designs of cam profiles have been developed to improve cam performance in high speed engines where circular arc cams have some shortcomings.

1. Juvinall, Robert C., 2012; "Machine Component Design", 5th Edition International Student Version, Wiley. Sections 9.13 and 9.14.

2. http://www.tildentechnologies.com/Cams/CamHistory.html see also other articles by this group.

Attachment:- Data.rar