Aims

1. To develop a systematic understanding and critical awareness of sustainable manufacturing systems, system design approaches and planning techniques applied to industry.

2. To enhance the acquisition of analytical knowledge and practical skills gained for analysing a complex manufacturing process or system and their integration using advanced computer design and modelling simulation tools.

3. To explore modelling simulation techniques to help create rapidly and turn innovative ideas timely into systems design, analysis and improvement particularly for a constraint-based production system in a virtual environment.

4. To become an expert in coping with the system uncertainty, examining the system random behaviour, refining the system design, and developing alternative operational management strategies based on the developed virtual prototyping system to a real industrial case study.

Unit learning outcomes

1. Critically appraise a systematic approach with lean thinking and apply it into analysis, planning, design and performance evaluation of a complex production system.

2. Identify and evaluate advances in discrete event simulation techniques and effective modelling methods used for development of a constraint-based production system providing an optimal or near-optimal solution with an aid of computer design and modelling simulation tools.

3. Improve the developed prototyping system by incorporating system characteristics of such as flexibility, reconfigurability and responsiveness with innovative features to create an efficient, cost-effective and eco-friendly manufacturing plant in a virtual environment.

Assessment strategies & instructions

The overall assessment strategy is designed to test problem solving capabilities through a case study in a virtual environment using computer-aided design and modelling simulation tools to satisfy LO 1, 2 and 3, with solutions developed and submitted in a report Each student is expected to develop their own computer models, which will be checked and questioned by the supervisor as part of the overall assessment.

The report should include the following information:

Unit Title - Virtual Systems Design and Simulation for Production

Unit Code - ENG770s2

1) Introduction/Background (refers to page 2-3 and your own research work)

2) Main work (refers to page 3-4)

3) Discussions and conclusions

References (if applicable)

Appendix (if applicable)

Background

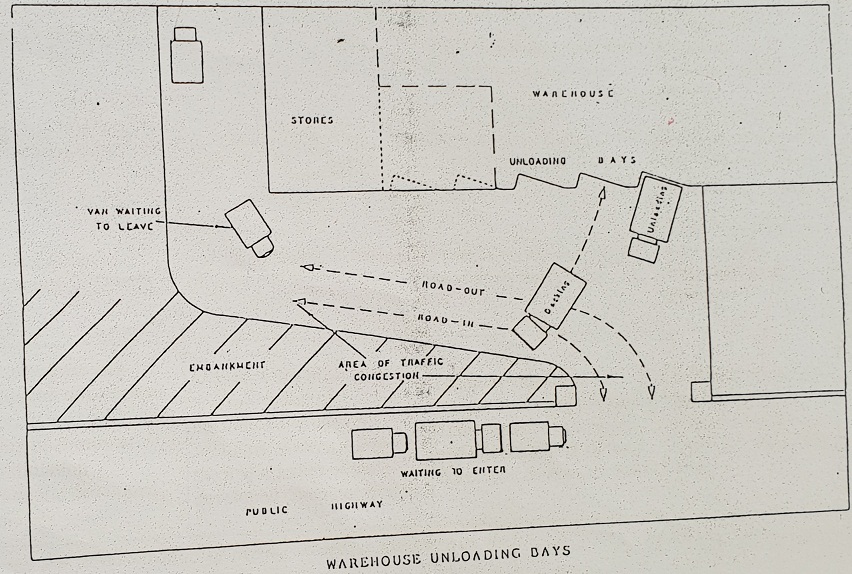

A manufacturing company wishes to invest a new warehouse (see an example in Appendix) as part of integration to serve the increasing demands required by customers. Critical factors in design and operation at the unload zone of the warehouse are given below:

1 The number of unloading bays.

2 The number of fork lift drivers required to service unloading.

3 The required size of the unload area (in terms of maximum number of pallets that can be held).

Goods will be brought to the centre in lorries; each lorry will carry a number of pallet-loaded goods. The pallets are unloaded to a temporary unload area, one at a time by the lorry drivers using a hand operated lift equipment. Pallets are then moved into the main storage areas within the warehouse by fork-lift trucks.

Removal of goods from the warehouse and individual items with local deliveries are made by the company's vans. The vans will be loaded at a large-goods outward area adjacent to the warehouse, which is not part of this study.

Several possibilities in operational conditions exist as follows:

| Option |

Number of Lorries / day (Avg) |

Available Times For arrival |

Arrival Pattern |

Unloading Pallets Time (min) |

Unloading Time Distribution |

| 0 |

63 |

07.30-15.00 |

Neg. Exponential |

7.00-11.00 |

Uniform |

| 1 |

65 |

07.00-15.30 |

Neg.Exponential |

6.00-12.00 |

Uniform |

| 2 |

61 |

08.00-15.00 |

Neg.Exponential |

6.00-12.00 |

Uniform |

| 3 |

60 |

08.00-15.00 |

Neg.Exponential |

6.00-14.00 |

Uniform |

| 4 |

62 |

07.00-15.00 |

Neg.Exponential |

6.00-15.00 |

Uniform |

| 5 |

65 |

07.30-15.30 |

Neg.Exponential |

7.00-15.00 |

Uniform |

| 6 |

60 |

08.00-15.00 |

Neg.Exponential |

7.00-14.00 |

Uniform |

| 7 |

68 |

08.00-15.00 |

Neg.Exponential |

6.00-12.00 |

Uniform |

| 8 |

62 |

08.00-15.00 |

Neg.Exponential |

6.00-14.00 |

Uniform |

| 9 |

75 |

07.00-15.30 |

Neg.Exponential |

6.00-14.00 |

Uniform |

| Option |

Number of Pallets/Lorry |

Pallet Number Distribution |

Time for Forklift Operation (min) |

Forklift Time Distribution |

Working Day For Forklift Operation |

| 0 |

23-Oct |

Uniform |

4-Feb |

Uniform |

09.00-17.30 |

| 1 |

16-Jun |

Uniform |

5, 1 |

Normal |

09.30-18.30 |

| 2 |

10-Apr |

Uniform |

3-Jan |

Uniform |

09.00-18.00 |

| 3 |

22-Dec |

Uniform |

4,1 |

Normal |

09.00-17.00 |

| 4 |

10-Apr |

Uniform |

5-Mar |

Uniform |

08.30-17.00 |

| 5 |

16-Jun |

Uniform |

5, 1 |

Normal |

08.30-17.00 |

| 6 |

22-Dec |

Uniform |

4-Feb |

Uniform |

09.30-18.30 |

| 7 |

10-Apr |

Uniform |

6, 1 |

Normal |

09.00-18.00 |

| 8 |

16-Jun |

Uniform |

1.5-2.5 |

Uniform |

09.00-18.00 |

| 9 |

16-Jun |

Uniform |

4, 1 |

Normal |

09.30-18.30 |

Note:

Lorry drivers park their vehicles at an empty bay and then commence unloading their pallets one at a time. If no bay is available then the drivers wait in the adjoining road until a bay beomes available.

Tasks

You should attempt to complete all the following tasks:

1. Evaluate the design based on your mathematical calculations and consider the main alternatives.

2. Provide a drawing of the unload zone as your initial design.

3. Develop a model in Enterprise Dynamics with the data provided.

4. Run the model and produce suitable numerical and graphical outputs. Analyse the data and make appropriate system design recommendations.

5. Modify your model by testing other possible scenarios that you consider closer to an optimum solution.

6. Suggest further developments to your model to evaluate how future growth in the business can be accommodated.

Note:

Make your own assumptions, this may refer to such as the availability of warehouse space and numbers of storage modules (storage racks) and locations, material-handling and transport systems and so on as part of the integrated manufacturing system. You may also consider how your system design may be able to cope with an increase in demands as well as product variances in future.