A mixture of methanol and water is to be separated in a new separation unit and you are needed to give a report detailing the design and costing of a distillation column with specifications illustrated below. The operating pressure is to be 1 atm and the feed temperature is 30° C.

Part A: Finding out the Thermodynamic data

1) Compare:

a) Ideal VLE data obtained by using Antoine's equation with VLE data obtained by using ChemCAD.

b) Ideal mixture.

c) Non-ideal mixture.

d) Data available in reference literature, by using Excel to generate a single plot displaying all your results. The plot must be in placed in the main part of your report. All numerical values are to be tabulated clearly (referred to from the main report) in an appendix in one table, that is, x-values in the first column and then one column of y-values from each computation method. (Separate hand-computations, and tables for each method, are not needed and must not be comprised.) Quote your literature sources clearly by using proper referencing format.

2) In brief describe the findings with particular emphasis on the appropriate of the thermodynamic model used in ChemCAD in predicting the thermodynamic data.

3) Make a clear recommendation of which method must be used and why.

Part B: Preliminary design

1) For the given specifications, find out the distillate and bottom flow rates, and also the light and heavy key splits into the distillate, for the column given the specifications above. (Make sure your mass balances over the column add up.)

2) Determine an average relative volatility from the experimental VLE data obtained in Part A. (Make sure you don’t emphasis some parts of the range more than others, that is, by comprising relatively more points between 0 and 0.1 than in the rest of range.)

3) Use the Fenske-Underwood-Gilliland (FUG) method supposing the constant average relative volatility to find out the number of theoretical stages N needed and also the feed point location NF (Kirkbride's method) to separate the mixture in a tray column supposing a total condenser and a kettle reboiler, using R/Rmin = 1.3. Quote the literature sources for your equations clearly.

4) By using the short-cut column model (SHOR) in ChemCAD, find out the number of theoretical phases N for the conditions given above supposing a) ideal mixture and b) non-ideal mixture.

5) Compare the estimates (ideal versus non-ideal mixture and hand calculations versus by using ChemCAD) and describe the effect on the design (over/under design and so on).

Part C: Detailed column design

1) By using the results from the short-cut computations as a starting point, find out the required number of phases in the column by using the rigorous SCDS ChemCAD model, a kettle reboiler and a sub-cooled condenser (20° C sub-cooling). Your design must have a reasonable (you define and describe) trade-off between first:

i) Column height N versus heat input QR with a fixed relative NF and then

ii) Feed location NF versus heat input QR for the N just found (optimizing based on QR indirectly considers reflux ratio R so don’t consider this separately). (When changing N, make sure you keep NF in its relative position, ex: a third from the top.) Describe the reasoning behind your choices.

2) For your final design, report the pressure, temperature, total mass and total molar flow rates and mole fractions of the product streams (in a Stream Box) and submit your PFD in the main report. Additionally, too report the number of phases, the reflux ratio, the feed location, the required heating and cooling duties (kW) in the report and comment on your findings (ex: accuracy, chosen design following column optimization, simple (that is, SHOR) model versus rigorous (that is, SCDS) model however on the same basis and so on).

Part D: Column sizing and costing

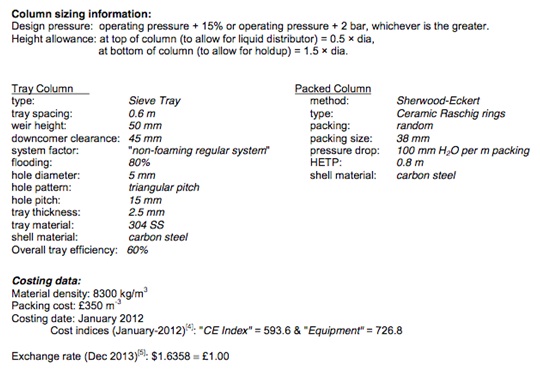

1) Find out the size (total height and diameter) and then the total purchased capital cost of the column section by using the data provided below for a) sieve trays and b) random packing by using ChemCAD. (Comprise a short ChemCAD report in appendix for each of the two final designs.)

2) Compute by hand the total column heights based on either the tray spacing and tray efficiency or the HETP. Tabulate the height with column diameter and purchased capital cost (in £) for each column alternative for simple comparison.

3) Present the relevant (you decide) technical and cost data (in £) for each alternative (although not in the form of ChemCAD printouts) and compare and describe these.

4) Make a clear proposal for which column type must be selected and why.