Supply Chain Assignment (Case Study)

A Supply chain reconfiguration case study:

The case company (referred to as ABC) is a leading supplier of maintenance, repair and operating (MRO) products to business and institutions in the United States, Canada and Mexico with an expanding presence in the Japan, India, China and Panama. The company works with more than 3,000 suppliers and offers nearly 900,000 products ranging from industrial adhesive used in manufacturing, to hand tools, janitorial supplies, lighting equipment, and power tools. When something is needed by one of their 1.8 million customers, it is often needed quickly. So, quick service and product availability are key drivers to ABC’s success.

Your assignment involves studying the US distribution network in ABC’s supply chain. ABC works with over 250 suppliers in China and Taiwan region. The suppliers produce products to ABC’s specifications and ship to the US using ocean freight carriers from four major ports in China and Taiwan. From these ports, products are shipped to US entry ports in either Seattle or Los Angeles. ABC currently has free on board (FOB) shipping contracts with Chinese and Taiwanese suppliers by which the supplier is responsible for all costs incurred until the product is delivered to the US entry ports. Approximately 40% of the containers enter in Seattle and 60% at the Los Angeles port. Containers on arrival at the port cities are inspected by federal agents. After passing through customs, products are loaded onto the 20-foot and 40-foot containers and are shipped by rail to ABC’s central distribution centre in Kansas City. Variable processing costs at both Los Angeles and Seattle ports are $5 per cubic meter (CBM). The rate for shipping the containers to Kansas City is $0.0018 per CBM per mile.

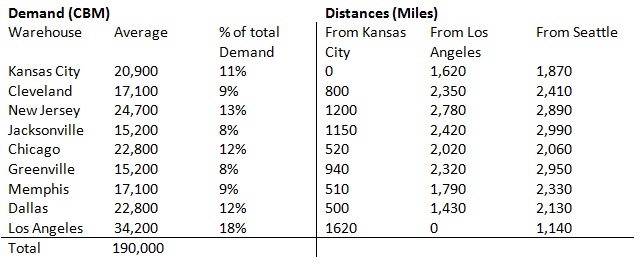

In Kansas City, the containers are unloaded and processed though a quality assurance check. This costs $3 per CBM processed. A negligible percentage of the material may need to be sent back to the supplier. Errors in quantity and package size are often found requiring accounting adjustments. Items are stored in Kansas City distribution centre, which serves nine warehouses in the US. The nine warehouses each place orders at the distribution centre that contains all the items to be replenished. Kansas City consolidates the items on order onto pallets and ships them on 53-foot trucks to warehouses. Truck freight cost $0.0220 per CBM per mile. The demand forecasts for the items purchased from China/Taiwan for next year and shipping distances are given in the following table:

Although a high percentage of demand was from warehouses in south and east of Kansas City, the problem has surfaced concerning the 18% that will be shipped to Kansas City and then shipped back to Los Angeles warehouse. This double-transportation could potentially be eliminated if a new distribution centre were built in Los Angeles. The idea might be to ship material arriving at the Seattle port by rail to a new Los Angeles distribution centre, which would be located at the current location of the Los Angeles warehouse.

It is estimated that the Los Angeles facility could be upgraded at a one-time cost of $1,500,000 and then operated for $350,000 per year. In the new Los Angeles distribution centre, containers would be unloaded and processed through a quality assurance check, just as is now done in Kansas City. The variable cost for doing this would be $5 per CBM processed, which includes the cost to move the containers from the Los Angeles port to the distribution centre. After the material is processed in Los Angeles, the amount needed to replenish the Los Angeles warehouse (approximately 18%) would be kept and the rest sent my rail to Kansas City. It would then be stocked in the Kansas City distribution centre and used to replenish the warehouses.

ABS management feels that it may be possible to make the change, but they are unsure if it would actually save any money and whether it would be a good strategic change.

problems to be addressed in your analysis:

problem 1. What would be the annual cost associated with running the existing system?

Note: In the existing system 40% of the volume arrives in Seattle and 60% in Los Angeles. All material is transferred to the Kansas City distribution centre by rail, where it is unloaded and quality checked. All volume is then transferred by truck to the nine existing warehouses in the US.

problem 2: What would be the annual cost associated with running the upgraded system?

Note: In the new system, the Los Angeles warehouse is upgraded to include a distribution centre capable of processing all the volume coming into the US. Containers coming into Seattle would be inspected by federal officials (it needs to be done at all port locations) and then immediately shipped by rail in their original containers to Los Angeles. All volume would be unloaded and quality checked in Los Angeles. 18% of the volume would then be kept in Los Angeles for distribution through that warehouse and the rest transhipped by rail to the Kansas City warehouse. The material sent to Kansas City would not need to go through another “unload and quality check process” and would be directly stored to supply the eight remaining warehouses in the US.

problem 3: What should be done based on your analysis of the US distribution system? Should the new Los Angeles distribution centre be added? Is this strategically something that ABC should do? What have they not considered that may be important?

Important notes for all assignment submissions:

While your experience and views are the essential components of your assignments, the appropriate use of literature is required to provide evidence-based suggestions.

You should include a list of all references you use in writing your assignments. Note that all assignments will be checked for originality (similarities to existing sources) on Turitin.

The assessment of your work will take into account (1) relevance of your answer to the problem or task set, (2) clarity of expression, (3) creativity/innovation, (4) citations beyond the given subject material, (5) logical planning and sequence, and (6) appropriate written and/or oral presentation of the work.

The Subject Text Book: Simchi-Levi, D., Kaminsky, P., and Simchi-Levi E. (2008) Designing and Managing the Supply Chain, 3rd ed. McGraw Hill.

References:

Chopra, S. and Meindl, P. (2012) Supply Chain Management : Strategy, Planning and Operation, 5th ed. Pearson.

Jacobs, F.R. and Chase R. (2012) Operations and Supply Chain Management: The Core, 3rd ed, McGraw Hill.